What is Machine Vision?

In today’s rapidly advancing technological landscape, machine vision has emerged as a crucial component in various automation processes across industries. It refers to the technology and methods employed to enable machines and systems to interpret visual information from the environment, enabling a wide array of applications, from quality control in manufacturing to navigation systems in autonomous vehicles. Understanding machine vision involves delving into its definition, core concepts, and how it operates as a complex system.

Definition and Core Concepts

Machine vision primarily leverages digital images processed through sophisticated algorithms to perform tasks that traditionally required human visual inspection. At its core, machine vision encompasses the capture, processing, and analysis of visual data, allowing machines to recognize and react to various stimuli based on the information gathered. This technology employs cameras and algorithms designed for specific tasks, ensuring not just accuracy and efficiency but also a significant reduction in operational costs.

How Machine Vision Works

The functioning of a machine vision system can be simplified into several key steps:

- Image Acquisition: Using specialized cameras, machine vision systems capture high-resolution images of objects. This can involve various types of cameras, from standard CCDs to more advanced 3D imaging systems depending on the requirements of the application.

- Image Processing: Once the image is captured, it is processed using algorithms that analyze the visual data. This can include filtering, edge detection, and contrast enhancement to prepare the data for analysis.

- Feature Extraction: The processing phase involves identifying unique features within the images relevant to the task at hand. This could include shapes, colors, and dimensions.

- Decision Making: After processing and extracting features, the system makes decisions based on predefined criteria. This could mean determining whether a product is defective or even guiding robotic assembly lines.

- Output and Control: Finally, the machine vision system outputs its findings, which can trigger other automated processes such as sorting products or alerting operators.

Key Components of Machine Vision Systems

Understanding the fundamental components of machine vision systems is crucial for grasping how they function. Below are the essential elements:

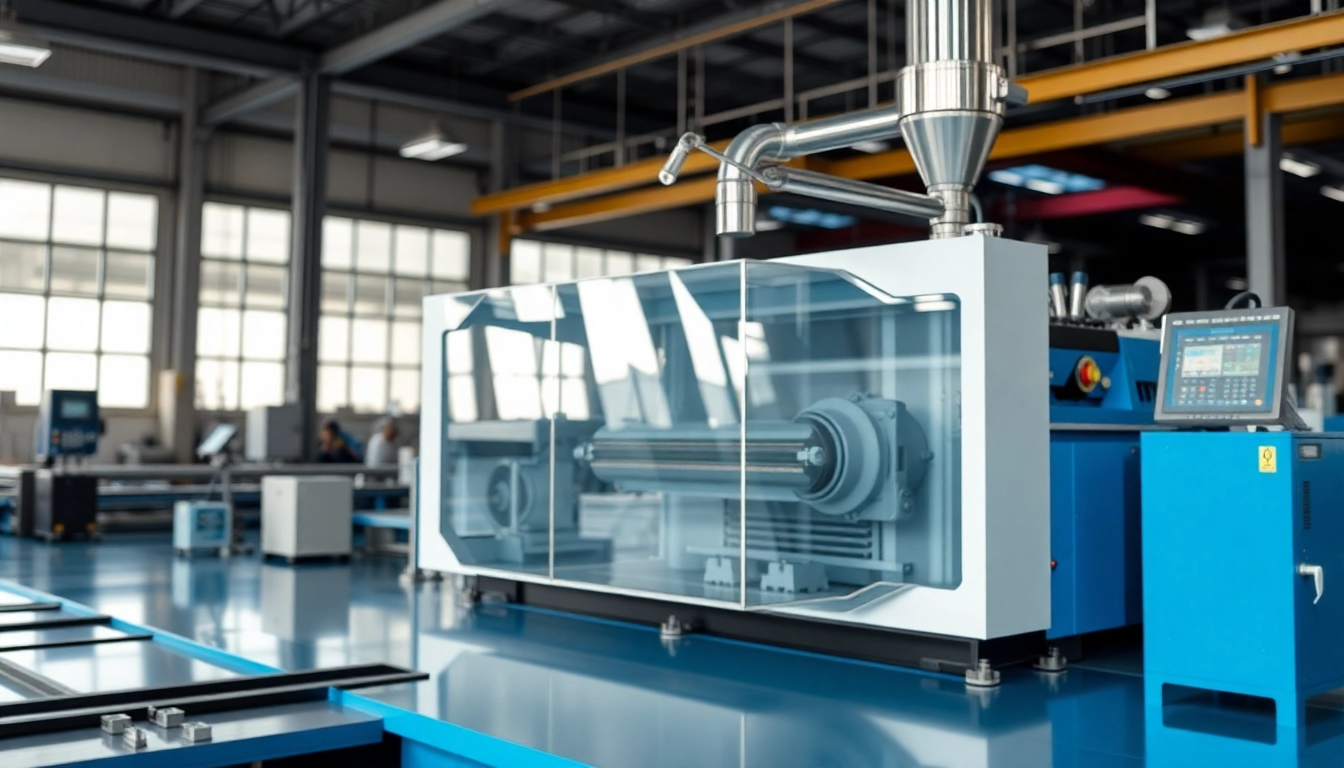

- Cameras: Cameras are perhaps the most crucial component of a machine vision system, responsible for image acquisition. Depending on the application, different camera technologies may be employed.

- Lighting: Proper illumination is indispensable in machine vision to ensure image quality. Various lighting techniques, such as LED light sources, can be utilized to minimize shadows and enhance contrast.

- Processing Hardware: The processing unit can be a PC or specialized hardware such as GPUs specifically designed for handling complex image processing tasks.

- Software: Software for machine vision includes image processing and analysis algorithms, often utilizing advanced tools like machine learning to improve accuracy and decision-making.

- Interfaces: Interfaces connect the components and allow communication between the cameras, processing units, and other systems, ensuring seamless functionality within an automated environment.

Applications of Machine Vision

The applications of machine vision span various sectors, each leveraging its capabilities to enhance efficiency, accuracy, and time management.

Machine Vision in Quality Control

One of the primary applications of machine vision is in quality control during manufacturing processes. By utilizing machine vision, companies can automatically inspect products to ensure they meet defined quality standards. This not only speeds up the inspection process but also increases accuracy, significantly reducing the occurrence of human error.

For instance, in the bottling industry, machine vision systems can check for defects such as incorrect labels or damaged containers, enabling manufacturers to manage quality proactively. A study showed that implementing machine vision in quality inspections led to a 30% reduction in waste and an increase in overall product quality.

Manufacturing and Automation Use Cases

Beyond quality control, machine vision plays a pivotal role in manufacturing automation. Systems can guide robotic arms for accurate assembly tasks, monitor production lines for process stability, and manage inventory through automated tracking. Industries such as automotive, electronics, and food processing benefit significantly from these capabilities.

For example, in automotive manufacturing, machine vision systems can monitor assembly lines for precision in component placement, ensuring that parts are fitted correctly. Such applications lead to enhanced productivity, as robots equipped with machine vision can work tirelessly, quickly identifying inconsistencies before costly errors occur.

Machine Vision in Consumer Products

In the consumer goods sector, machine vision technologies enhance product usability and consumer experience. Machine vision systems can help automate the packaging process, ensuring that products are packaged efficiently and accurately.

Consider unpackaged snacks: machine vision can ensure that each bag has the correct amount of chips, adjusting the production process accordingly to minimize waste. Furthermore, as consumers become increasingly aware of quality and safety, the implementation of machine vision systems provides brands with a way to demonstrate their commitment to quality assurance.

Comparing Machine Vision and Computer Vision

While machine vision and computer vision are often used interchangeably, they are distinct areas of technology with unique functionalities and applications.

Fundamental Differences

Machine vision is primarily focused on automating industrial tasks through visual data interpretation, while computer vision is broader, encompassing any task that involves understanding visual information, often aided by artificial intelligence. In essence, machine vision can be viewed as a subset of computer vision, applying specific technologies and methodologies tailored for industrial applications.

Use Cases and Industry Applications

In terms of applications, machine vision is heavily employed in automated manufacturing and industrial inspection, while computer vision finds relevance in areas such as healthcare, security, and augmented reality. For example, computer vision technologies can power facial recognition systems, healthcare imaging analysis, and real-time video analytics—tasks that go beyond the industrial scope of machine vision.

Integration and Synergies Between Technologies

Despite these differences, both fields are interrelated. Employment of machine vision systems can be enhanced by advancements in computer vision, particularly through the integration of machine learning algorithms that improve detection rates and reduce false positives. By tapping into the latest developments in AI, machine vision systems can benefit from improved accuracy and adaptability to new situations.

Challenges in Implementing Machine Vision

Despite the advantages and wide-ranging applications, implementing machine vision technologies does not come without its challenges.

Technical Limitations and Solutions

Technical limitations represent one of the significant hurdles in adopting machine vision. Issues such as varying lighting conditions, occlusions, and the need for high-resolution images can impede performance. Solutions to address these challenges include utilizing advanced lighting techniques and selecting suitable cameras that can adapt to different operational environments. Continuous advancements in technology are also making machine vision systems more robust against these challenges.

Training and Maintenance Considerations

Effective training and maintenance of these systems are just as critical. Machine vision systems require careful calibration and ongoing updates to algorithms to maintain efficiency, which can be time-consuming and require professional expertise. Ensuring that staff are well-trained in operating and maintaining these systems will help mitigate downtime and performance issues.

Cost-Effectiveness Analysis

Initially, the setup costs for machine vision systems can be significant, especially for small to mid-sized enterprises. However, a comprehensive cost-effectiveness analysis can reveal that the long-term savings and efficiency gained from implementing these technologies often outweigh the initial investment. Automated systems can significantly reduce labor costs, increase production speed, and improve product quality—all of which contribute to overall profitability.

Future Trends in Machine Vision Technology

The future of machine vision appears bright, particularly as technological advancements continue to shape its development and application.

Advancements in AI and Machine Learning

One of the most influential trends is the integration of AI and machine learning into machine vision systems. These advancements allow for more sophisticated data analysis and enable systems to learn from previous inspections to improve over time, adapting to new scenarios and reducing errors.

As this technology evolves, we can expect machine vision systems to become more versatile and capable of performing increasingly complex tasks across a variety of sectors.

Impact of IoT on Machine Vision

The Internet of Things (IoT) is also set to redefine machine vision. With more devices being interconnected, machine vision systems can now gather and analyze data in real time, leading to faster and more informed decisions. For instance, factories equipped with IoT-enabled machine vision systems can optimize workflows and achieve greater operational transparency.

Predictions for Industry Growth

Industry analysts predict substantial growth in the machine vision sector, driven by increased adoption across various applications from robotics and automation to healthcare and retail. As companies increasingly rely on data-driven decisions, the demand for precise and reliable machine vision technologies will likely continue to soar, creating opportunities for innovation and advancement.