Introduction to Blow Molding Machines

In the realm of manufacturing, especially within the plastics industry, the Blow Molding Machine stands out as a pivotal tool. These machines are specifically designed to create hollow plastic products by molding molten plastic into shapes. This sophisticated process is not just about efficiency; it’s also about precision, quality, and adaptability across various industry applications.

Definition and Purpose

Blow molding is a manufacturing process used to create hollow plastic parts. This technique involves inflating molten plastic inside a mold to form various shapes such as bottles, containers, and even components in the automotive industry. Its primary purpose is to produce lightweight yet durable products that meet the rigorous demands of modern applications.

Types of Blow Molding Processes

Blow molding can be classified into three primary types: extrusion blow molding (EBM), injection blow molding (IBM), and injection stretch blow molding (ISBM). Each type serves unique purposes and offers different advantages. For instance, EBM is often utilized for large containers like bottles, while IBM is ideal for precise, high-quality parts.

Applications in Various Industries

The applications of blow molding are vast and varied, spanning numerous industries including:

- Consumer Products: Everyday items such as beverage bottles and containers.

- Automotive: Fuel tanks, air ducts, and various under-the-hood components.

- Medical: Disposable containers and apparatus needed in healthcare settings.

- Industrial: Storage tanks and specialized equipment for different sectors.

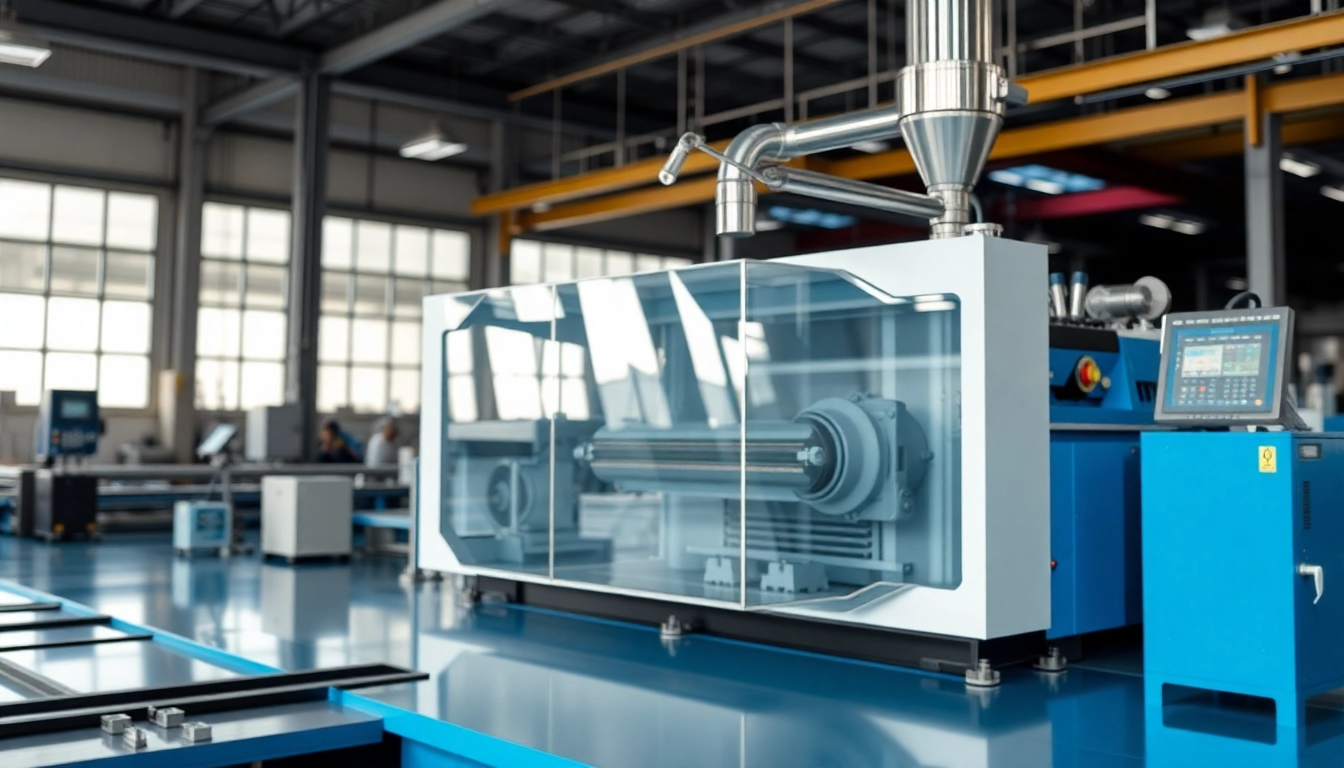

Key Components of Blow Molding Machines

Understanding the structure of blow molding machines is crucial for optimizing their performance and ensuring longevity. They are equipped with several key components that play significant roles in the molding process.

Understanding the Molding Process

The blow molding process generally follows these steps:

- Heating: Plastic pellets are heated until they become molten.

- Forming the Preform: The molten plastic is formed into a parison (a hollow tube).

- Molding: The parison is heated and then inflated into a mold using air pressure.

- Cooling: The molded part is cooled and solidified before being ejected from the mold.

Essential Machine Parts

Key components of blow molding machines include:

- Extruder: Responsible for melting and transporting the plastic.

- Mold: Shaped component where the blown part is formed.

- Blow Pin: Injects air into the parison to expand it inside the mold.

- Control System: Manages the machine’s operations and settings.

Technological Innovations

Recent advancements in technology have significantly enhanced blow molding machines. These innovations include:

- Servo Motors: For improved speed and precision in movements.

- Advanced Sensors: To monitor and optimize the process in real-time.

- Energy-saving Features: Reducing overall operational costs and environmental impact.

Benefits of Using Blow Molding Machines

Implementing blow molding technology offers numerous benefits that enhance productivity and sustainability.

Cost Efficiency and Speed

One of the primary advantages of blow molding machines is their cost efficiency. They allow for rapid mass production of plastic parts, which drastically reduces per-unit costs. Additionally, the automated processes minimize labor costs and human error, leading to more consistent output.

Quality and Precision in Production

Blow molding machines are designed to produce high-quality products with precise dimensions. Their ability to maintain tight tolerances ensures that the final products meet stringent quality standards, which is particularly important in industries such as automotive and medical.

Sustainability and Material Use

Modern blow molding practices focus on sustainability. Companies are increasingly adopting eco-friendly materials, including recyclable plastics, which can help conserve resources and reduce waste. Moreover, the production process is optimized to minimize energy consumption.

Choosing the Right Blow Molding Machine

When selecting a blow molding machine, it’s essential to consider several factors to ensure optimal performance and return on investment.

Factors to Consider

Key considerations include:

- Type of Product: Determine whether extrusion, injection, or stretch blow molding is needed.

- Production Volume: Assess the machine’s capacity to meet production demands.

- Material Compatibility: Ensure the machine can work with the required plastic materials.

- Budget Constraints: Evaluate both initial costs and long-term operating expenses.

Popular Brands and Models

Several reputable brands are known for manufacturing reliable blow molding machinery, including:

- Wilmington Machinery: Renowned for high-speed, efficient blow molding systems.

- Parker Hannifin: Offers a range of blow molding machines with advanced features.

- Bekum: Focuses on innovative, eco-friendly molding solutions.

Maintenance and Support

Regular maintenance is vital to the longevity of blow molding machines. Companies should ensure they have access to good customer support, spare parts, and maintenance services to minimize downtime and keep production running smoothly.

Future Trends in Blow Molding Technology

The blow molding industry is continually evolving, influenced by technological advancements and changing market demands.

Smart Automation in Manufacturing

The integration of smart automation and Internet of Things (IoT) technologies is on the rise. These innovations enable more efficient operations and data-driven decision-making, enhancing overall productivity and reducing waste.

Eco-Friendly Material Innovations

As sustainability becomes a pressing concern, the use of biodegradable and bio-based materials in blow molding is expected to increase. Manufacturers are actively seeking ways to reduce their environmental footprint while maintaining quality.

Market Demand and Growth Projections

The demand for blow molding machines is projected to grow, driven by the booming consumer goods market and greater emphasis on high-quality packaging solutions. Experts forecast steady growth in the coming decade, particularly in emerging markets where plastic consumption is rising.