Understanding Laminating Resin

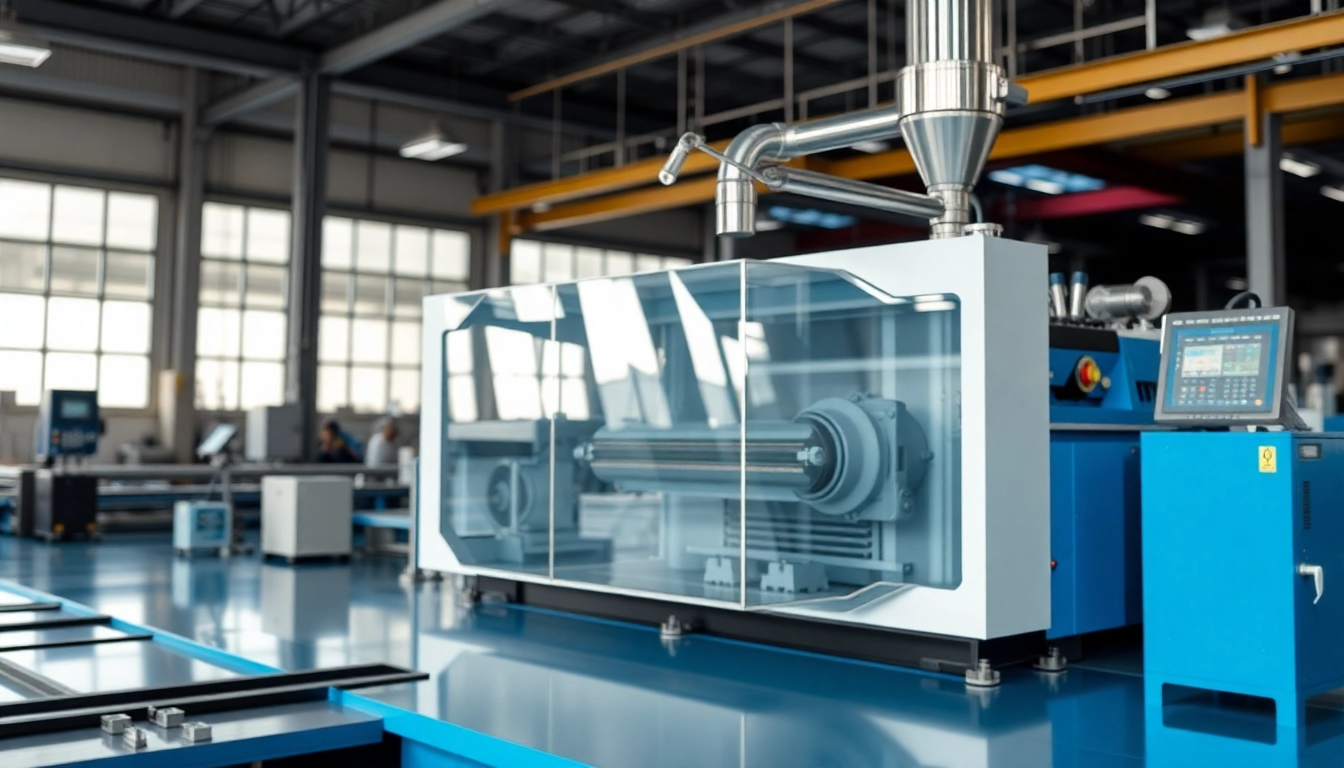

Laminating resin is an essential material widely used in various industries, particularly in composite manufacturing. As the demand for durable and lightweight materials rises, understanding the composition, types, and applications of laminating resin becomes increasingly important for engineers, contractors, and hobbyists alike.

Definition and Composition

Laminating resins are specialized polymers used in composite fabrication processes, primarily for reinforcing materials such as fiberglass, carbon fiber, and aramid fiber. These resins are characterized by their ability to bond well with reinforcement materials, offering enhanced structural strength and rigidity. Typically, laminating resin consists of resin systems like polyester, epoxy, or vinyl ester, each with distinctive properties suited for specific applications.

Types of Laminating Resin

There are several types of laminating resin, each serving unique purposes:

- Polyester Laminating Resin: This is the most common type used in marine applications. It provides excellent adhesion and is cost-effective, making it popular in boat manufacturing.

- Epoxy Laminating Resin: Known for its superior bonding strength and resistance to harsh environmental conditions, epoxy-based resins are preferred in applications demanding high performance, such as aerospace and automotive industries.

- Vinyl Ester Laminating Resin: Combining attributes of both polyester and epoxy, vinyl ester resins are used in applications that require chemical resistance and lower shrinkage during curing.

Applications in Various Industries

The versatility of laminating resin is evident across numerous fields:

- Marine: Used extensively for boat hull construction and repairs, polyester laminating resin is favored for its ability to withstand corrosive marine environments.

- Aerospace: In this sector, epoxy laminating resin plays a critical role in creating lightweight, high-strength components essential for aircraft performance.

- Construction: Laminating resins are applied in manufacturing structural components such as beams and panels, enhancing the overall integrity of buildings.

- Automotive: Manufacturers utilize laminating resin for producing parts that meet both safety and performance standards, contributing to the efficiency of vehicles.

Benefits of Using Laminating Resin

Durability and Strength

The primary advantage of using laminating resin is its remarkable durability. When properly applied, laminating resin forms a tough, resilient matrix that can resist mechanical stress, impact, and environmental factors. This durability translates to longer-lasting products, reducing both replacement and maintenance costs.

Versatility in Projects

Laminating resin can be tailored for a wide range of projects. Whether crafting intricate designs or constructing robust structures, the adaptability of laminating resin allows designers and engineers to meet diverse requirements. This flexibility makes it an invaluable asset in prototyping and production.

Cost-Effectiveness Comparisons

When evaluating the economic benefits of laminating resin, it is crucial to consider not only the initial material cost but also the lifespan and performance outcomes. While some high-end resins like epoxies may have a higher upfront cost, their longevity and compatibility can result in significant savings over time.

How to Work with Laminating Resin

Preparation and Tools Required

Before beginning any project involving laminating resin, proper preparation is essential:

- Work Area: Ensure the workspace is clean, well-ventilated, and free from dust.

- Tools: Common tools needed include mixing containers, stir sticks, brushes, rollers, and safety gear such as gloves and masks.

- Materials: Familiarize yourself with the types of reinforcement materials you plan to use and purchase corresponding laminating resins accordingly.

Step-by-Step Application Process

The application of laminating resin typically follows these steps:

- Mixing: Carefully measure and mix the laminating resin and hardener according to the manufacturer’s instructions.

- Application: Using a brush or roller, apply an even layer of resin onto the prepared surface.

- Layering: Position the reinforcement material onto the wet resin, ensuring full saturation, and apply additional resin on top.

- Curing: Allow the assembly to cure completely as per the specified time — usually between several hours to days.

Safety Measures and Best Practices

Working with laminating resin necessitates adherence to safety protocols:

- Always wear appropriate personal protective equipment (PPE).

- Ensure good ventilation to mitigate exposure to fumes.

- Follow all manufacturer guidelines for mixing and application to avoid any health risks.

- Store resins in accordance with safety regulations to prevent accidents.

Common Problems and Solutions

Understanding Common Issues

Laminating resin usage is not without its challenges. Understanding common problems can help in managing them effectively:

- Bubble Formation: Air bubbles can form during mixing or application, leading to weak spots.

- Inadequate Curing: Insufficient curing can result from incorrect mixing ratios or low ambient temperature.

- Poor Bonding: Failure to achieve proper adhesion may arise from contaminated surfaces or incorrect resin selection.

Effective Troubleshooting Tips

For common problems encountered while using laminating resin, consider the following solutions:

- To eliminate bubbles, gently tap the surface with a brush or tool while the resin is still wet.

- For inadequate curing, assess the ambient conditions and adjust as necessary; using heat lamps can accelerate curing in cold situations.

- Ensure surfaces are clean—free of oils, dust, or grease—before applying resin to enhance bonding.

Preventing Future Problems

Adopting preventive strategies can minimize potential issues:

- Conduct trials on small sections to optimize your mixing and application techniques.

- Keep a log of materials and methods used in past projects to identify what works best.

- Regularly review and update your safety protocols based on new information and materials.

Conclusion and Further Resources

Summary of Key Takeaways

Understanding laminating resin, its varieties, and applications is pivotal for anyone involved in composite manufacturing. The material’s durability, versatility, and cost-effectiveness demonstrate its importance across various sectors.

Recommended Reading and Guides

For those looking for additional information, resources that explore detailed techniques and advanced applications of laminating resin can help enhance your expertise in the field.

Engaging with Laminating Resin Community

Connecting with fellow users and experts in forums and online communities can provide valuable insights, troubleshooting tips, and innovative ideas for using laminating resin in projects.