Understanding Infusion Resins

The Basics of Infusion Resins

Infusion resins represent a critical component in the composite manufacturing industry, providing the necessary adhesive properties and structural integrity to advanced composite materials. These resins are typically used in conjunction with glass, carbon, or aramid fibers, forming the backbone of many industrial applications ranging from aerospace to marine construction.

During the infusion process, a resin mixture is introduced into a dry fibrous preform under vacuum pressure. This method ensures that the resin penetrates all areas of the material, promoting complete wet-out of the fibers while minimizing air entrapment. Interested manufacturers often turn to infusion resins for their ability to balance viscosity and performance characteristics, leading to superior final products.

Common Applications in Composite Manufacturing

Infusion resins are widely utilized in various sectors, demonstrating versatility in application. Some common uses include:

- Aerospace: Building parts like wing spars and fuselage components that require high strength-to-weight ratios.

- Marine: Crafting hulls and other structural components that resist water absorption while maintaining strength.

- Automotive: Manufacturing lightweight, durable car parts, contributing to fuel efficiency and performance.

- Wind Energy: Creating turbine blades designed for optimal performance and longevity in harsh environments.

Key Benefits of Using Infusion Resins

Utilizing infusion resins offers several benefits that can elevate the quality and performance of composite materials:

- Enhanced Strength: Infusion resins provide exceptional mechanical strength and durability.

- Superior Finish: The infusion process results in a smoother surface finish, reducing the need for post-processing work.

- Controlled Flow: Low-viscosity options facilitate better flow, enabling complete impregnation of the fiber and minimizing voids.

- Cost Efficiency: Although some infusion resins may have a higher upfront cost, the reduction in labor and enhanced performance can lead to lower overall project costs.

Types of Infusion Resins

Epoxy-Based Infusion Resins

Epoxy resins are widely regarded for their exceptional bonding capabilities and resistance to environmental factors, making them a popular choice in the infusion process. They offer high thermal stability and excellent mechanical properties, which are crucial for applications in the aerospace and automotive industries.

Moreover, epoxy resins can be tailored to achieve specific cure times and viscosity levels. This variability allows manufacturers to select formulations that best suit their infusion techniques and desired characteristics of the final composite product.

Polyester vs. Vinyl Ester Infusion Resins

Polyester and vinyl ester resins are other commonly used alternatives to epoxy resins in composite applications. While polyester resins provide quick curing times and are generally less expensive, they may not match the performance specifications of epoxy resins concerning strength, chemical resistance, and thermal stability.

On the other hand, vinyl ester resins bridge the gap between polyester and epoxy options, offering improved mechanical properties and increased resistance to environmental degradation. Choosing between these resins depends on the specific requirements of the application, including cost constraints and performance objectives.

Specialty Infusion Resins for High-Performance Needs

Beyond standard formulations, there exist various specialty infusion resins tailored to meet high-performance demands. These include:

- High-Temperature Resins: Designed to maintain structural integrity under extreme heat conditions.

- Biocomposites: Formulated from renewable resources to provide an eco-friendly alternative for various applications.

- Low Toxicity Resins: Made for industries requiring stringent safety measures, such as aerospace and healthcare.

Process of Using Infusion Resins

Preparation and Setup for Infusion

Successful infusion processes begin with proper preparation. This includes:

- Mold Preparation: Ensure the mold is clean and properly coated with a release agent to allow for easy demolding after curing.

- Dry Fiber Placement: Position fibers in the mold according to the desired lay-up scheme. It’s crucial to avoid any wrinkles or foreign material that could compromise the infusion.

- Vacuum Bagging: Create a sealed environment around the mold using a vacuum bag to facilitate air removal.

Conducting a Successful Infusion Process

Once prepared, the infusion process can commence. Key steps include:

- Evacuating the Mold: Use a vacuum pump to remove air from the mold until the desired vacuum level is achieved.

- Introducing the Resin: Allow the infusion resin to flow into the dry fiber through a designated inlet point.

- Monitoring Flow: Observe resin distribution to ensure complete wet-out of all fibers and observe for any potential blockages.

Post-Infusion Curing Techniques

After the infusion is complete, the composite structure will undergo curing. The curing stage may involve:

- Room Temperature Cure: Allow the composite to cure at ambient temperature for standard applications.

- Heat Curing: Utilize an oven or heating blanket to expedite the curing process and enhance properties like strength and durability.

Challenges with Infusion Resins

Common Issues Faced in Infusion Processes

While resin infusion is a highly effective method, multiple challenges can arise. Commonly encountered issues include:

- Inadequate Bonding: Resulting from improper surface preparation or incorrect resin choice.

- Air Entrapment: Occurs due to poor vacuum levels or improper fiber placement.

- Inconsistent Resin Flow: Can be caused by variations in resin viscosity or resistance in the fiber structure.

Best Practices to Overcome Challenges

Addressing infusion challenges requires a proactive approach. Some best practices include:

- Thorough Training: Ensuring all personnel understand the infusion process and potential pitfalls.

- Pre-Infusion Testing: Conducting small-scale trials to refine techniques and assess compatibility.

- Continuous Monitoring: Keeping track of real-time infusion parameters to catch issues early.

Continuous Improvement in Resin Infusion Techniques

The infusion industry is ever-evolving, with continuous improvements being made to techniques and materials. Engaging in regular training sessions, participating in industry workshops, and staying informed on the latest innovations are vital to remaining competitive in the market.

Future Trends in Infusion Resins

Sustainable Innovations in Infusion Resins

One significant trend is a growing focus on sustainability. As industries strive to minimize their environmental impact, the development of bio-based and recyclable resins has become increasingly important. Innovations in sustainable materials could revolutionize the infusion resin market by providing eco-friendly alternatives without compromising performance.

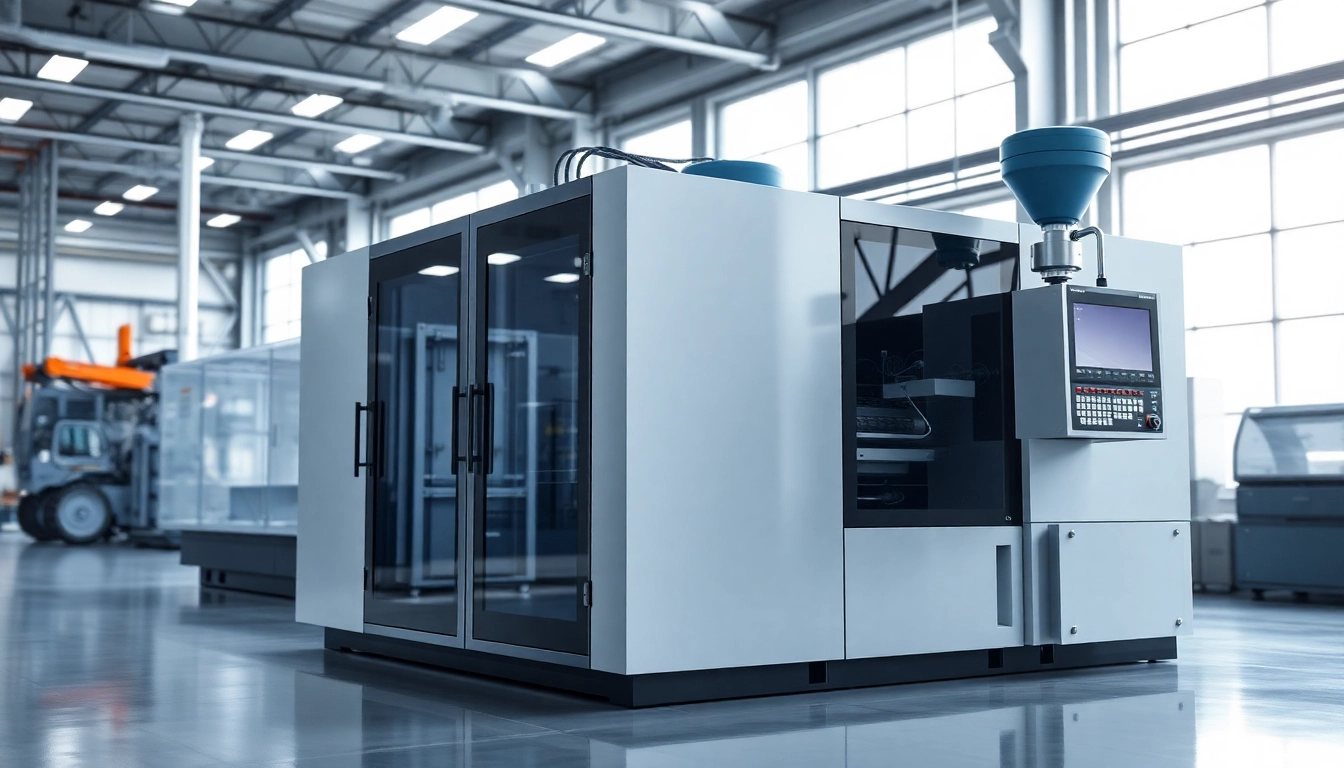

Technological Advancements Impacting Infusion Processes

Technological advancements are also shaping the future of infusion resins. Innovations in automated fiber placement and advanced monitoring systems significantly enhance the precision of resin application, ensuring optimal results while reducing waste. Additionally, improvements in simulation and modeling software allow manufacturers to predict performance outcomes more accurately.

The Role of Infusion Resins in Emerging Industries

Emerging industries, such as electric vehicle manufacturing and renewable energy, present new opportunities for infusion resins. The demand for lightweight and high-strength materials is escalating, making infusion resins an ideal solution. As these sectors expand, the versatility and performance of infusion resins will continue to be integral to their technology advancements and design principles.